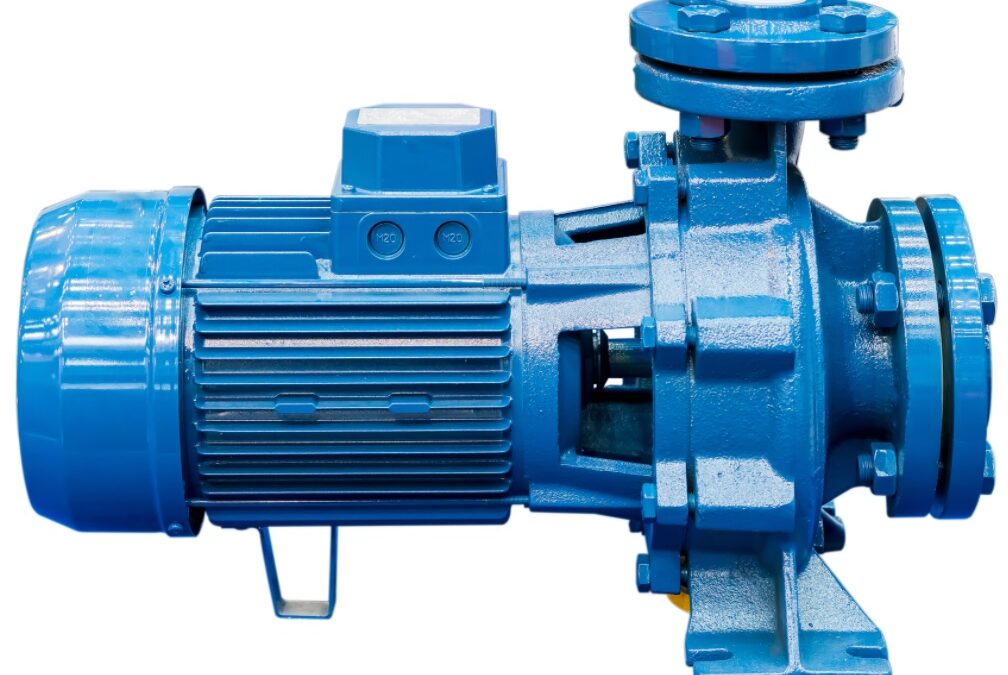

Choosing the wrong pump for your commercial or industrial application is even more expensive because you may suffer significant downtime or damage when the pump malfunctions. You must keep in mind that there are many aspects to picking the right pump based on your needs in terms of pressure, suction, temperature, flow, gravity, and more. These aspects help you determine the kind of pump you need for your business.

Here is a deeper look into the aspects to evaluate when choosing a pump for your business.

Fluid viscosity

You should choose a pump designed to handle the consistency or viscosity of the fluid you intend to pump so that it does not become clogged or degraded by slurry or debris. Note that some liquids are subject to changing their consistency under pressure, for example, when they encounter a rotating impeller in the pump. Some become thinner while others become thicker with increasing force. Other liquids like water do not change their viscosity regardless of the pressure. Positive displacement pumps are known to provide a constant flow at any given pump speed.

Flow rate

You also need to determine the flow rate when evaluating different pumps at PumpBiz because the pump you choose dictates the flow rates you can achieve. You can calculate your intended flow rate by multiplying the total volume by the time you wich the liquid to move. Suppose you have a 500gallon water feature that requires full circulation once every hour; in that case, a pump with a minimum rated flow of 500gallon per hour is suitable.

Fluid temperature

Knowledge of the processing temperatures helps with pump selection because temperature-sensitive fluids are likely to change their flow properties with temperature changes. Although different pumps can operate at a wide range of temperatures, be careful if you want a pump that suits liquids hotter than 200degrees Fahrenheit. Ideally, the pump you choose should be rated for the maximum temperature of the fluid you intend to pump. Knowing the fluid type and viscosity under different processing temperatures is essential.

Differential pressure

This refers to the difference in force between the pump inlet and outlet. The pressure on the inlet side is called the net positive suction head, and pumps vary in how much pressure they require on that side. That is why your pump vendor will likely ask questions about the system’s components before the pump, including filters, valves, line sizes, and lengths. These aspects affect the net positive suction head as the liquid enters the pump.

Fluid density

The fluid density refers to the fluid’s weight by volume. When a liquid is denser, that means it has more weight. For instance, water is less viscous than corn syrup. Knowing how the fluid’s density compares to water is vital to choosing a pump whose curves align with your business needs.

The bottom line

Pumps are only a vital part of your processing system, and selecting the right one ensures it functions efficiently. It is advisable to sketch a design of your processing system to help communicate your needs to the pump vendor. Most importantly, understand the fluid properties the pump will handle.

Related posts

Recent Posts

- Sustainability Redefined: How Keter Group Brings the Blueprint For Better Living With Lakeside Collection October 30, 2023

- Tradingview: Unleashing the Revolutionary Power of Trading August 28, 2023

- 6 Features That Make Cantilever Racking a Smart Investment August 3, 2023

- Achieve Radiant Skin with French Professional Skin Care Brands July 10, 2023

- Use of technology and products for People with Kidney Stones June 19, 2023

- Uncovering New Opportunities for Your Medical Billing Business May 6, 2023

- 10 Reasons to Invest in Automated Insurance Claims Software May 6, 2023